Examples of Problem

Frequently Asked Questions (FAQ)/Heat exchangers in operation

Various plate heat exchanger problem might occur such as corrosion, fatigue cracking, and deformation in

heat transfer plates and deformation and swelling in plate gaskets.

We will take a look at cases that occurred in the past, and introduce countermeasures to keep in mind when operating PHEs.

Problem that occurs in plate heat exchangers

Plates

Entire surface corrosion

Corrosion-resistant metals such as stainless steel have a stable oxidation film called a passivation film on their surface. With entire surface corrosion, the corrosion progresses without the formation of this passivation film. Therefore, it progresses uniformly over the entire surface, and the surface can lose its metallic luster and become rough.

Crevice corrosion

This is a common type of corrosion for stainless steel, and it occurs frequently even in plate heat exchangers.

It is corrosion that occurs in areas where there are structural gaps, gasket sealing surfaces, and gaps in precipitates.

Since the environment in such gaps tends to be low in dissolved oxygen, the passivation film is broken down over time and corrosion progresses.

Erosion-Corrosion

Erosion-corrosion is a type of corrosion in which the film on the metal surface is peeled off due to continuous collision with slurry in the fluid, resulting in deep, localized erosion.

Generally, it tends to occur in places where the flow velocity increases locally, such as in the narrow and bent parts of pipes. The rate of progression depends on the type of metal and fluid, the temperature, and the flow conditions of the fluid.

Stress corrosion cracking

This is a phenomenon in which cracks start from corrosion in metal, due to external stress acting on the material or internal stress in the material.

In areas in which such stress occurs, degradation of oxide film, movement of atoms, and pores occur easily. If these areas are exposed to a corrosive environment, corrosion will happen imminently.

Stress accelerates the progress of corrosion, leading to cracking and breakdown.

Fatigue cracking

This is a phenomenon in which a material is broken down through repeated exposure to a force.

Even under a low load that does not normally cause breakdown, repeated exposure can lead to localized plastic deformation (deformation that does not recover even if the external force is removed), causing a small crack to progress to a full breakdown.

Deformation

The main causes of deformation on heat transfer plates are excessive tightening, contamination with foreign matter, and the swelling of plate gaskets. There are also cases in which it is caused by water hammer action. Water hammer action occurs in a penstock pipe when the flow of water is suddenly shut off, and the inertia of the water causes impacts, vibration, and water pressure inside the pipe. In the case of plate heat exchangers, it happens if the pump starts/stops or the valves open/close too fast. It can cause serious trouble, such as deformation in the contact points around gasket grooves or on plate surfaces.

Freeze cracking

This occurs when a plate heat exchanger is operated in such a way that the water inside the PHE freezes, such as when heat is exchanged between water and low-temperature fluid below freezing point and the low-temperature fluid flows through the heat exchanger ahead of the water, or if there is water remaining in the heat exchanger when it is shut down in an environment where the outside temperature is below zero. Generally, if freezing and thawing are repeated during operation and shutdown, the heat transfer plates will deform due to volume expansion as the water freezes, leading to cracking.

Plate gaskets

Deformation

The main causes of deformation in plate gaskets are improper gasket installations and sudden fluctuations in pressure.

If a plate gasket is deformed, sufficient sealing pressure cannot be maintained, leading to external leakage.

Swelling

If a plate gaskets has low chemical resistance, fluid will enter between the molecules of the plate gasket and cause it to swell.

The swelling of plate gaskets will result in external leakage due to meandering or lead to excessive compression of heat transfer plates.

In order for a plate heat exchanger to operate normally, it is necessary to select an appropriate plate gasket material that meets specifications.

Examples of plate problem

Examples involving corrosion

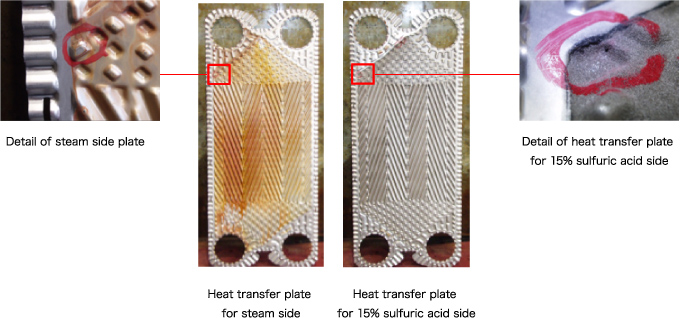

Used to heat sulfuric acid x steam for 1 year and 2 months

Entire surface corrosion

? Period of use: About 1 year and 2 months

? Plate material: UNS N10276 (Equivalent to Hastelloy C-276)

? Fluid used: 0.2MPa steam/15% sulfuric acid

? Operating temperature: 135°C /90°C

? Applications: Sulfuric acid steam heater used in the pickling process of products

? Phenomenon:

It is believed that entire surface corrosion started on the sulfuric acid side. This caused penetrating cracks.The plates on the steam side show no signs of corrosion. Although there is little corrosion near the sulfuric acid inlets (lower part of the heat transfer plates), corrosion is progressing near the sulfuric acid outlets (the upper part of the heat transfer plates) where the temperature rises due to heating. This has caused corrosion with a decrease in plate thickness.

? Cause:

The steam temperature is too high. Since the wall temperature near the outlets on the sulfuric acid side rises almost to the steam temperature, it is believed that partially heated sulfuric acid caused significant corrosion that lead to penetrating cracks.

? Measures:

Measures for prolonging the life of the heat transfer plates against entire surface corrosion include changing the plate material type and changing to thicker heat transfer plates. In addition, when there is a difference in the progress of corrosion between the upper and lower parts of the heat transfer plates (as in this case), the orientation of the heat transfer plates can periodically be reversed top to bottom to prolong their life.

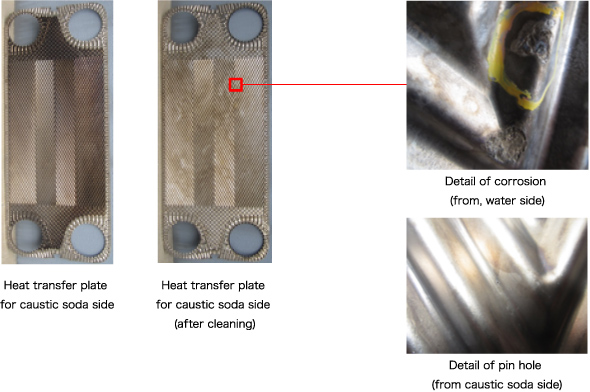

Used to cool caustic soda x cooling water for 4 years and 5 months

Crevice corrosion

? Period of use: About 4 years and 5 months

? Plate material: NW2200 (pure nickel)

? Fluid used: 32% caustic soda/cooling water

? Operating temperature: 100°C

? Application: Caustic soda coolers in the caustic soda concentration process

? Phenomenon:

When the equipment was disassembled, a large amount of scale was found adhered to the plates on the cooling water side. After cleaning, penetrating holes due to corrosion were found at the contact points between heat transfer plates. The plates on the caustic soda side show no signs of corrosion.

? Cause:

It is believed that the scale that had adhered to the contact points between the heat transfer plates on the cooling water side resulted in a concentration of Cl- in the cooling water, which led to the progression of crevice corrosion and the generation of penetrating holes.

? Measures:

Since plate heat exchangers have structures that include many gaps, such as the gaps between heat transfer plates and plate gasket and the contact points between heat transfer plates, it can be said that the equipment is susceptible to crevice corrosion. Since crevice corrosion is more likely to occur when scale adheres to the gaps within the structure of the equipment, it is important to remove scale through periodic disassembly cleaning. Although the plate material (NW2200) has good corrosion resistance to caustic soda, the presence of Cl- causes crevice corrosion. In addition to periodic disassembly cleaning, the reduction of Cl- and other water quality controls are also required.

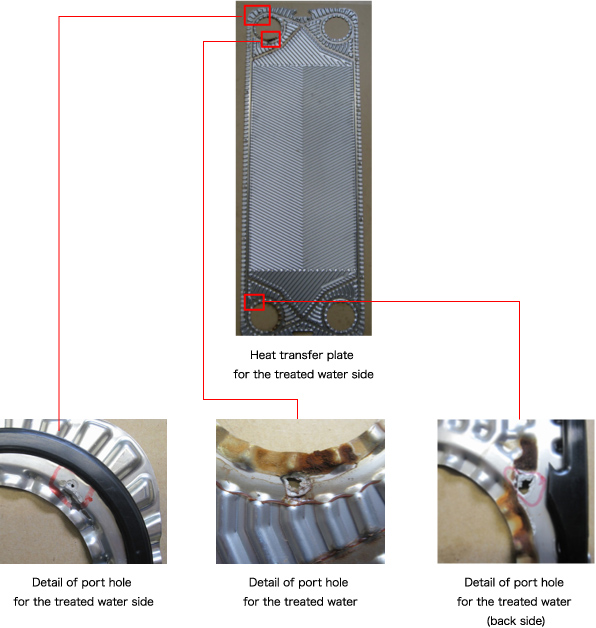

Used to cool treated water x filtered water for about 2 years

Crevice corrosion

? Period of use: About 2 years

? Plate material: SUS304

? Fluid used: Treated water/filtered water

? Operating temperature: 50°C

? Application: Cooler for treated water

? Phenomenon:

Scale accumulated in the gap between the heat transfer plates and plate gaskets on the treated water side, causing corrosion that led to penetrating holes.

? Cause:

Stainless steel has sufficient corrosion resistance to neutral water, but if the oxidation film on the surface is broken down to some cause, such as by a Cl- attack or the adhesion/peeling of foreign matter to the surface, corrosion will start at and progress from that point. It is believed that after corrosion started, it progressed as crevice corrosion due to scale adhesion.

? Measures:

Measures to be considered include changing the plate material to SUS316, which has good resistance to crevice corrosion, improving the water quality to reduce Cl-, and periodic disassembly cleaning to reduce the accumulation of scale.

The adhesion of scale not only causes corrosion as in this example, but also increases pressure loss and decreases the heat transfer performance.

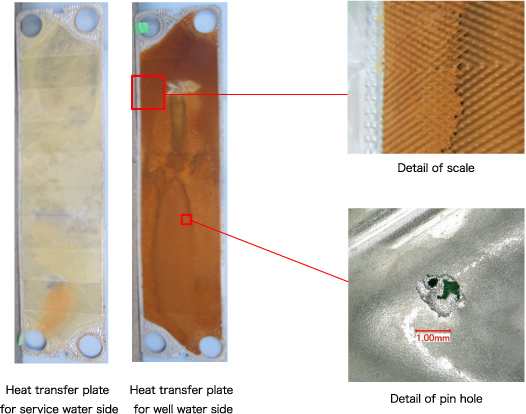

Used to cool tap water x well water for 3 years

Crevice corrosion

? Period of use: About 3 years

? Plate material: SUS316

? Fluid used: Tap water/well water

? Operating temperature: 41°C

? Application: Tap water cooler

? Phenomenon:

Scale had adhered to the entire surface of heat transfer plates on the well water side, and on the plate transfer surfaces signs of corrosion were found on the contact points between heat transfer plates and on free surfaces. Based on the results of an investigation, the scale was found to be an oxide composed mainly of Fe.

? Cause:

It is believed that crevice corrosion occurred due to the adhesion of Fe oxide scale. Generally, Fe content rusts when it comes into contact with stainless steel. When that happens, the deposits cause a concentration of Cl-, creating an environment that facilitates the breakdown of the oxidation film.

? Measures:

Regular disassembly cleaning is recommended to reduce the adhesion of scale to heat transfer plates.

The adhesion of scale not only causes corrosion as in this example, but also increases pressure loss and decreases the heat transfer performance.

Used to cool water x water for 19 years

Crevice corrosion

? Period of use: About 19 years

? Plate material: SUS304

? Fluid used: Water

? Operating temperature: 40°C

? Application: Water cooler

? Phenomenon:

Maintenance has been performed when there is a high level of pressure loss in the equipment. In recent years, penetrating holes have been found in the heat transfer plates during maintenance. Soft scale had adhered to the heat transfer plates, and penetrating holes appeared in some areas, such as near the portholes and the heat transfer surfaces, due to corrosion.

? Cause:

It is believed that the scale resulted in the concentration of Cl-, leading to the progress of crevice corrosion.

? Measures:

Since the equipment has been used for a long time, it was determined that the maintenance method and frequency are appropriate. The timing of maintenance varies depending on usage conditions such as drops in performance, increases in pressure loss, gasket replacement, and corrosion in heat transfer plates.

We recommend setting an appropriate maintenance cycle based on the operating status of the equipment.

Used to cool sulfuric acid x refrigerant for 3 months

Erosion-Corrosion

? Period of use: About 3 months

? Plate material: SUS315J1

? Fluid used: 35% sulfuric acid/refrigerant

? Operating temperature: 50°C

? Application: Sulfuric acid cooler in the surface treatment process

? Phenomenon:

A reddish brown scale had adhered to the surfaces of the heat transfer plates on the sulfuric acid side, and entire surface corrosion was observed.

In addition, on plates on the sulfuric acid side, there was a significant reduction in wall thickness near the portholes where the flow velocity increased, resulting in the generation of penetrating holes.

? Cause:

It is believed that corrosion products (caused by entire surface corrosion due to sulfuric acid) flowed near the portholes, resulting in wear on the heat transfer plates that had become brittle due to corrosion, leading to the progress of erosion-corrosion. This occurred because the plate material is not suitable for 35% sulfuric acid.

? Measures:

It is necessary to change to a plate material that has high corrosion resistance to sulfuric acid. In this example, the plates were updated to UNS N10276 (equivalent to Hastelloy C-276).

The corrosiveness of sulfuric acid varies greatly by concentration. It is necessary to select a material that is suitable for the usage conditions.

Used to recover heat from hot water x hot spring water for 7 months

Stress corrosion cracking

<Example 1>

? Period of use: About 7 months

? Plate material: SUS316

? Fluid used: Hot water/Hot spring water

? Operating temperature: 150°C

? Application: Binary power generation using hot spring water as a heat source

? Phenomenon:

Waste in the hot water flowed into the equipment, and accumulated at the bottoms of the heat transfer plates.

? Cause:

Crevice corrosion occurred due to concentration of Cl- ions accumulated between unwanted materials and heat transfer plates. These ions will break down the oxidation film of the stainless steel. Tightening load and operating pressure causes stress that leads to crack. The cracks are believed to be stress corrosion cracks that started from crevice corrosion.

? Measures:

The factors that cause stress corrosion cracking are corrosive environment, the presence of continuous stress, and the characteristics of the material. It is believed that stress corrosion cracking will not occur if one of these factors is removed. Therefore, applicable measures include reducing the amount of foreign matter flowing into the equipment, carrying out periodical disassembly cleaning to prevent the accumulation of foreign matter, and changing the plate material to a material with a higher corrosion resistance.

In addition, the flow of unwanted material into the equipment not only causes corrosion as in this example, but also increases pressure loss and decreases the heat transfer performance.

Examples other than corrosion

Used to cool vinegar x cooling water for 3 months

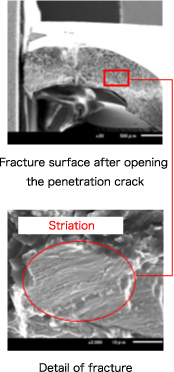

Fatigue cracking

? Period of use: About 3 months

? Plate material: TP270

? Fluid used: Vinegar/Cooling water

? Operating temperature: 60°C

? Application: Vinegar cooler

? Phenomenon:

Penetrating cracks were generated at the contact points of adjacent heat transfer plates on the vinegar side, and wear marks that suggested rubbing between heat transfer plates were found nearby. In addition, striations, which are traces of repeated stress, were found on the fracture surfaces of the penetrating cracks. Based on the results of actual pressure measurements, it was found that the pressure on the cooling water side fluctuated momentarily.

? Cause:

It is believed that these are fatigue cracks that were caused by repeated stress on the contact points of the heat transfer plates on the vinegar side, due to fluctuations in pressure on the cooling water side.

? Measures:

Since fatigue cracks occur during short-term operation, it is necessary to reduce the fluctuations in pressure. Regarding other countermeasures, it is possible to replace the heat transfer plates with thicker plates to increase their strength, and to retighten the heat transfer plates to suppress vibration due to fluctuations in pressure.

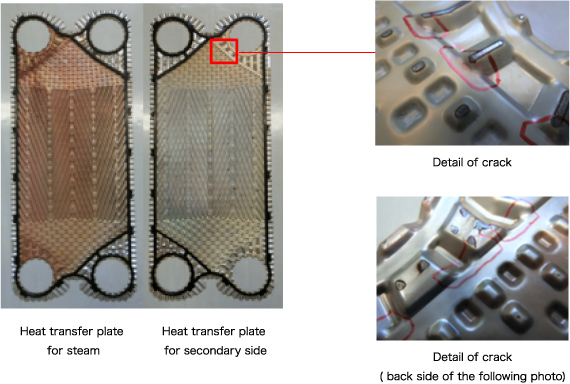

Used to heat steam x secondary water for 1 year and 11 months

Fatigue cracking

? Period of use: About 1 year and 11 months

? Plate material: SUS316

? Fluid used: Steam/secondary water

? Operating temperature: 144°C

? Application: Secondary water heater

? Phenomenon:

Penetrating cracks occurred near the portholes of the secondary water outlet on the heat transfer plates on the secondary water side. There was no sign of corrosion near the penetrating cracks or deformation in the heat transfer plates. However, wear marks that suggested rubbing between heat transfer plates were observed. Although wear marks were found on both the front surfaces (secondary water side) and the back surfaces (steam side) of the heat transfer plates, there was significant wear on the front surfaces.

? Cause:

It is believed that penetrating cracks are caused by fatigue cracking due to repeated pressure. Since the cracks occurred near the steam inlet, it is believed that they were caused due to pressure fluctuations at the steam inlet.

? Measures:

It is necessary to adjust the steam control valve to mitigate steam pressure fluctuations.

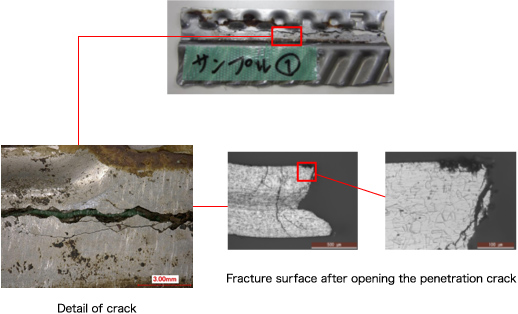

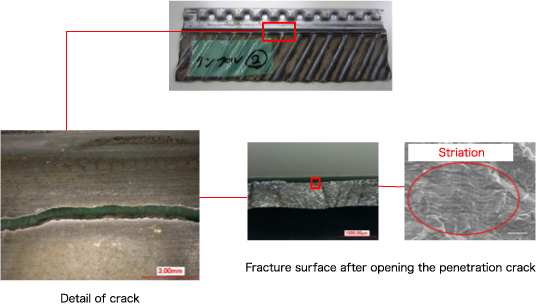

Used to recover heat from process fluid x process fluid for 1 year

Fatigue cracking

? Period of use: About 1 year

? Plate material: SUS316 (t0.8)

? Fluid used: Process fluid

? Operating temperature: 120°C

? Application: Process fluid heater

? Phenomenon:

During a short period of operation, external leakage occurred due to penetrating cracks. Penetrating cracks occurred on or near the gasket seal lines on heat transfer plates, with crack shapes due to mechanical force.

? Cause:

The features of stress corrosion cracking and fatigue cracking were observed in cross-sections and on fractured surfaces. However, based on the areas of damage, it is believed that fatigue cracking was the main cause of the penetrating cracks.

The damaged parts were in locations that are constrained by the contact points between plate gaskets and heat transfer plates, where fatigue cracking does not normally occur. If the plate arrangement is assembled incorrectly, such damage could occur because the contact points of one heat transfer plate do not contact the adjacent plate.

? Measures:

Install every other heat transfer plate upside down. If the heat transfer plates are arranged continuously in the same orientation, they could become deformed or cracked even if they do not leak however it might depend on the operating pressure. For more information about plate arrangement, please refer to "element configuration diagram" and "instruction manual".

Used to lubricating oil x cooling water for 1 month

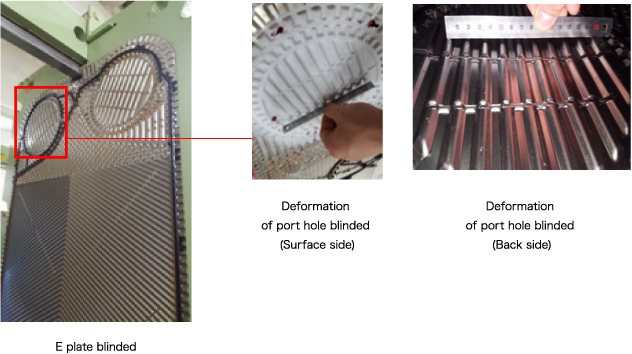

Deformation

? Period of use: About 1 month

? Plate material: TP270

? Fluid used: Lubricating oil/Cooling water

? Operating temperature: 60°C

? Application: Lubricating oil cooler

? Phenomenon:

External leakage occurred between the E. frame and an E plate during a trial run. The closed porthole on the E plate was warped and deformed in the direction of the pipe, and penetrating cracks were found.

? Cause:

As in this example, closed portholes can become deformed during operation in which negative pressure is generated suddenly and/or repeatedly.

? Measures:

We recommend reviewing the operating conditions so that negative pressure does not occur suddenly and/or repeatedly during operation of the equipment or when operation is stopped.

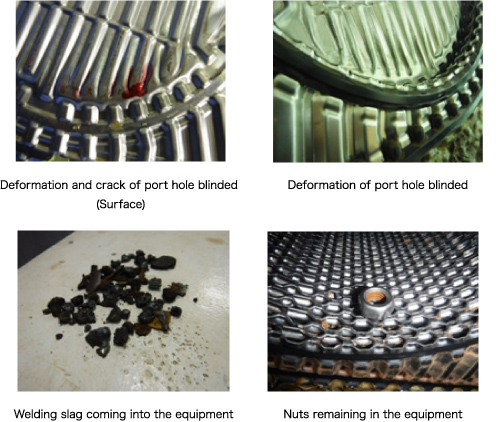

Used to cool fresh water x seawater for 11 months

Deformation

? Period of use: About 11 months

? Plate material: TP270

? Fluid used: Fresh water/seawater

? Operating temperature: 50°C

? Application: Fresh water cooler

? Phenomenon:

External leakage occurred between the E. frame and the E plate, and when the equipment was disassembled, deformation and penetrating cracks were found in the heat transfer plates on the portholes of the fresh water inlet of the E plate. In addition, welding slugs and nuts, which are believed to have been used during piping work, were found in the portholes of the plates on the fresh water inlet side.

? Cause:

The weld slugs and nuts assumed not to be during HISAKA manufacturing process have been used during the installation of piping. It is believed that waste item from these items flowed into the equipment and repeatedly collided with it, resulting in deformation and damage to the heat transfer plates.

? Measures:

To prevent unwanted material from entering the equipment, be sure to perform sufficient flushing when connecting the pipes. The inflow of unwanted material into the equipment causes not only deformation and damage to the heat transfer plates as in this example, but also increases pressure loss and reduces heat transfer performance due to the blockage of flow channels.

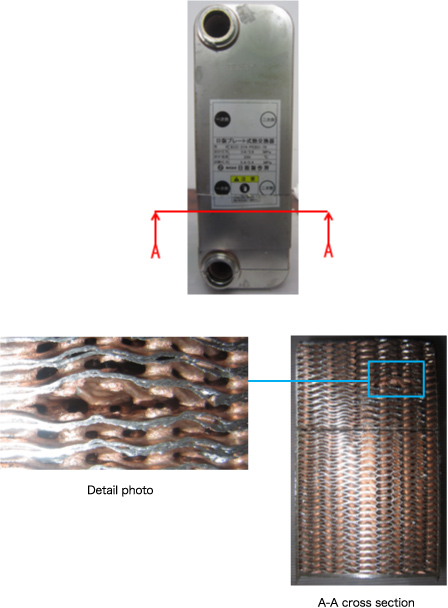

Used to cool refrigerant x water for 11 months

<Example>

? Period of use: About 11 months

? Plate material: SUS316 (with brazing copper)

? Fluid used: Refrigerant/water

? Operating temperature: Refrigerant 0°C or less

? Phenomenon:

The heat transfer plates were greatly deformed and cracked, and the two fluids were mixed.

? Cause:

The refrigerant temperature dropped below zero, causing the water to freeze and the volume to expand, leading to deformation in the heat transfer plates. Plate deformation gradually increased due to repeated freezing and thawing during operation, and the heat transfer plates eventually fractured.

? Measures:

It is necessary to manage the operation so that the refrigerant temperature does not drop below 0°C.

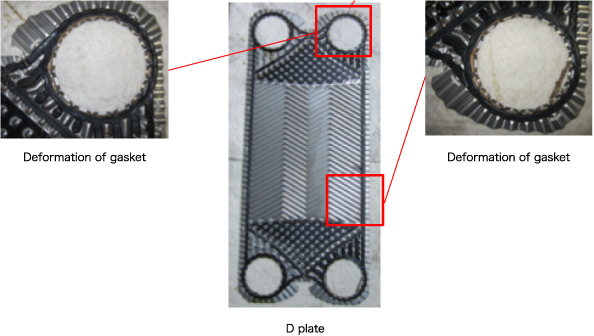

Examples of gasket problem

Gasket used to cool lubricant oil x boiler water supply for 1 month

Deformation

? Period of use: About one month after replacing the gasket

? Gasket material: NBR

? Fluid used: Lubricant/boiler water supply

? Design pressure: 1.2 MPaG

? Application: Lubricating oil cooler

? Phenomenon:

Shortly after starting operation, the boiler water supply leaked out from between the S. frame and the D plate. When the equipment was disassembled, meandering was found in the D gasket. During operation, fluctuations in pressure from 0.5 to 1.0 [MPaG] were repeated every few minutes by controlling the pump on the water supply side of the boiler.

? Cause:

For example, it is believed that repeated fluctuations in pressure led to meandering in the D gasket and a decrease in seal pressure, causing external leakage.

? Measures:

It is necessary to install a pressure reducing valve in the inlet piping for boiler water supply in order to mitigate fluctuations in pressure. In addition to repeated fluctuations in pressure, note that when using a plate heat exchanger sudden fluctuations in pressure within a short time might cause the seal pressure to drop temporarily, leading to external leakage.

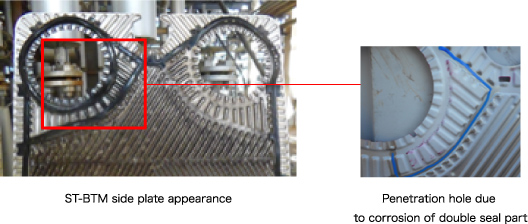

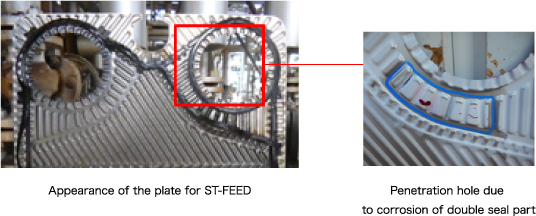

Gasket used to recover heat from ST-FEED x ST-BTM for 1 year

Swelling

? Period of use: About 1 year

? Plate material: SUS316L

? Fluid used: ST-FEED/ST-BTM

? Operating temperature: 130°C

? Application: Heat recovery

? Phenomenon:

The equipment was shut down with fluid remaining inside. The equipment was started again 1 year later, and immediately an external leak occurred.

Leakage was observed on both fluid sides. Rough areas, believed to be corrosion, and penetrating holes were found in double seals, which normally do not come into contact with the heat transfer plates.

After the equipment was disassembled, the gaskets were stretched to the extent and they could not be reattached. The thickness of the gasket had increased and their hardness had decreased.

? Cause:

It is believed that the swelling of the plate gaskets caused a drop in the surface pressure of the seals and leakage of fluid, leading to concentrated and localized corrosion at the double seal.

? Measures:

Above all, it is important to select gaskets that are suitable for the usage conditions. Before using a fluid that could cause swelling of the gaskets, we recommend conducting an immersion test with the actual fluid to determine the appropriate plate gasket material.