HISAKA Maintenance Full Service Package

What is the Full Service Package?

"Full Service Package" is a maintenance service provided by HISAKA.

Skillful technicians who are familiar with design know how to take care of the heat exchanger and maintain it. Your heat exchanger will be returned to you with as new unit.

- Clean

- Chemical cleaning is used to remove stubborn stains that cannot be removed by regular jet cleaning.

Your heat exchanger will be returned to you with the frame looking as good as new. -

[Before cleaning]

[Before cleaning] [After cleaning]

[After cleaning]

- Peace of Mind

- If plate penetration is discovered during the final test of the Full Service Package, a PT inspection is performed to determine the point of penetration and to estimate its cause.

Also, the manufacturer keeps parts in inventory to ensure the shortest possible restoration time. -

- Fast

- Your heat exchanger is cleaned, tested, and returned in standard 7 days after full service package.

Full Service Package Workflow

Degreasing tank / cleaning

After pre-cleaning, the heat transfer plates are placed in a chemical solution to remove the oils and unwanted material.

Plate gaskets that have been attached with adhesive are peeled off. The adhesive will be removed so the parts can be cleaned.

Jet cleaning

Stubborn dirt that could not be completely removed by immersion cleaning is removed by jet cleaning.

Completion inspection

After the heat transfer plates are cleaned, and gaskets are attached, the plates are then assembled on the frame, tightened to the specified dimensions, and then conduct a pressure resistance test.

Heat exchanger is checked to ensure no leakage before shipping.

Other Maintenance Services

We also send our service engineers to customers who find it difficult to use the Full Service Package due to time and/or space constraints.

? On-site maintenance

We send our well trained service engineers to your site.

This is convenient for customers who have lack manpower to perform plate cleaning on site or never clean the plate heat exchanger before

Dedicated maintenance tools such as automatic tightening machines and hot water jets are used to perform this work.

Automatic tightening machine

Uniform tightening is required when assembling a plate heat exchanger.

Using an automatic tightening machine allows ideal tightening to be achieved in a short time, without the need for any special skills.

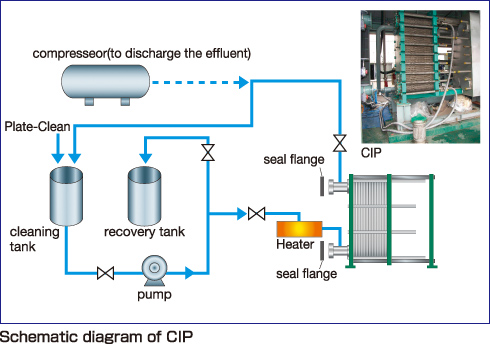

? Cleaning in place (CIP)

Cleaning in place (CIP) of a PHE makes it possible to remove stubborn scale and interior contaminants and to return performance to nearly the same level as new. However, if disassembly cleaning is not possible, HISAKA also provides cleaning in place (CIP) services. We provide a cleaning service with our "Plate-Clean" product dedicated for plate heat exchangers at our customers' sites.

Also, using "Plate-Clean" to perform circulation cleaning can wash away or dissolve and remove scales before stubborn stains are formed. This recovers performance and is effective for extending the disassembly cycle of plate heat exchangers.

Maintenance menu comparison

Maintenance evaluations for off-site (work performed at Hisaka) and on-site (work performed at the customer's site) are shown in the following table. Select the type of maintenance that best fits your situation.

| Disassembly | Cleaning Result | Regasketing | Working Hours | Working Place | |

| Full Service Package | Yes | Very good | Yes (depending on the condition) |

7 days or more | Off-site |

| On-Site Maintenance | Yes | Bad to Good | Yes (depending on the condition) |

Depends on model | On-site |

| CIP (Cleaning in place) | No | Bad to Very good | No | About 2 days | On-site |