Evaporator‐Concentrator system

- At the concentration on extracts, fruit juice, dairy products, soy milk, and sugar solution,

we propose a suitable system according to the characteristics of liquid and installation conditions

while minimizing thermal effects on flavor, color and vitamin content.

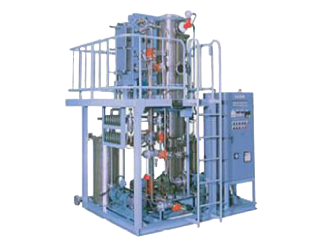

Plate type concentration evaporator

(MFE/LEP: membrane flow system)

Evaporation amount:-10000 [kg/h]

Applicable viscosity:-1000 [cp]

-

System / machine

Long plate type

One-pass concentrator

(REN-MFE) -

Operation

Membrane-flow evaporation

Evaporate while flowing down inside of the plate in thin membranous flow. -

Features

・Reduce thermal effects

・Large-volume concentration

・Energy saving with multiple utilities

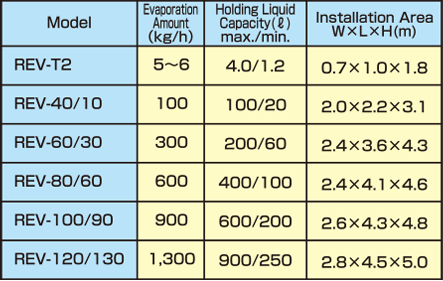

Flash type evaporator

(REV : Forced circulation type)

Evaporation amount:-2000[kg/h]

Applicable viscosity:-2000 [cp]

-

System / machine

Plate type

flash evaporator

(REV) -

Operation

Flash evaporation

After heating with the plate, flush-evaporate with the separator. -

Features

・Suppressing the foaming of liquid

・High versatility

・Small-volume test machine is available

Global evaporator

(GY : Coil rotation type)

Evaporation amount:-1000 [kg/h]

Applicable viscosity:-10000 [cp]

-

System / machine

Coil rotation type

Global evaporator

(GY) -

Operation

Coil membrane-flow evaporation

Evaporate while the heat transfer tube is rotating in the separator. -

Features

・Suitable for solid-containing liquids

・Applicable to high viscosity

・High recovery rate of concentrated liquid

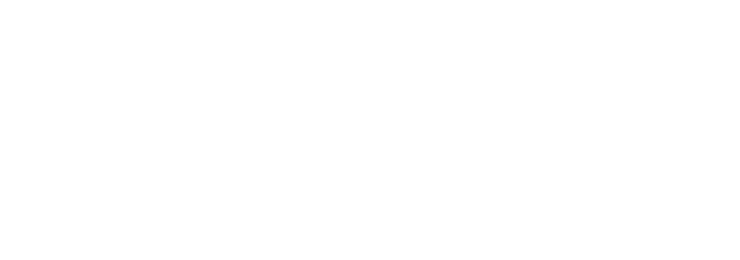

- Plate type concentration evaporator(MFE/LEP: membrane flow system)

- Suitable for mass-production by suppressing the scaling and thermal effect

See more

- Plate type concentration evaporator(MFE/LEP: membrane flow system)

- Suitable for mass-production by suppressing the scaling and thermal effect

- Long plate type one-pass concentrater(MFE: Membrane flow system)

The one-pass system with super-long plate, which minimizes the amount of holding liquid in the equipment, secures high quality concentrate for such as liquids that are emphasized fragrance or sensitive to heat. Depending on the evaporation amount, the plates are available in three different sizes.

Features

- Concentrate without compromising the properties of the stock solution by completing the process from receiving of the stock solution to the extraction of the concentrated liquid in a few minutes.

- Minimizing the amount of holding liquid in the equipment supports a small-volume production of a wide variety of products.

- There is no stagnating of the treatment liquid with super-long plate, one-pass concentration system is highly efficient and low cost.

- Suitable for steam compressor types, thermo-compressor types, and of course multiple-effect types, also reusing of steam is effective for energy saving.

- Since the liquid always flows at high flow rate, the scale is greatly reduced.

- The compact vertical shape of evaporation plate saves space for installation area.

Applications

| Juices | Orange, apple, grape, pine, tomato |

|---|---|

| Extracts | Chicken bone, meat, seafood, vitamins, enzyme, yeast |

| Sugars | Liquid that need to prevent coloring, decomposition, or deterioration of oligosaccharides and honey |

| Milk and others | Liquid that need to be concentrated in a short time |

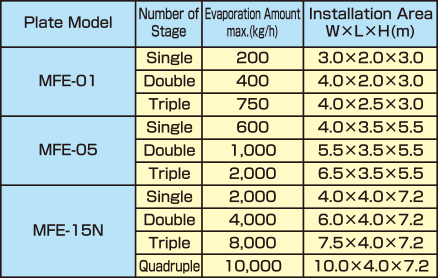

- Plate type evaporator(LEP: Membrane flow system)

The stock solution, which is pre-heated and entered in the evaporator, is self-evaporated by the temperature difference between the inside of the equipment, instantly heated and evaporated at the plate surface.

The circulation of the considerable capacity liquid increases the speed, and the scale becomes difficult to adhere to the plate surface.

Features

- Because the mass velocity is high and the distribution of the liquid is uniform, the operatione is difficult to adhere.

- The heat transfer performance is three to five times higher than conventional multi-tube type.

- Short processing time, and the liquid contacts with the heat transfer surface about 2 seconds, suitable for heat-sensitive liquid.

- The circulation system is adopted to cope with changes in the stock solution.

- Easy to disassemble, easy to wash plates and increase or decrease the number of plates.

- Fully automated operation from start to cleaning with a single button.

- Stainless and titanium are available for the plate material.

Applications

| Food | Milk, soy protein, liquid sugar, sucrose, isomerized sugar, glucose, starch syrup, various soup solutions, fish juice, high-concentration food wastewater |

|---|---|

| Fermentation | Alcohol distillation wastewater, various fermentation wastewaters, various organic acid aqueous solutions |

| Chemical | Caustic soda, glutamate soda, high concentrated industrial drainage |

| Fiber and paper | Mercerized wastewater recovery, hair washing wastewater, dyeing wastewater, SP-SCP valve waste water, pulp fermentation wastewater |

| Machinery and electric | Water soluble waste oil, plating wastewater, animal-plant fat oil wastewater |

- Flash type evaporator(REV : Plate type forced circulation type)

- Suitable for the concentration of highly foaming liquid, continuous or batch operation is possible.

See more

- Flash type evaporator(REV : Plate type forced circulation type)

- Suitable for the concentration of highly foaming liquid, continuous or batch operation is possible.

Evaporation concentrator is a small and fully automated equipment performing flush-evaporation in the separator tank after heating the liquid with plate heat exchanger.

Not only concentrating of small-volume liquids, capable of operating that suppresses the foam completely in a variety of highly foaming liquids.

Features

- Operating while crushing the foams also supports the concentration of the forming liquid.

- Highly adaptable tester that handles high viscosity liquids up to approximately 10,000c.p.

- The device repeating the batch operation achieves a large cost reduction and space saving by a compact design.

- Fully automated operation from the start-up to the washing process is achieved by the programming control.

- Complete continuous operation is also possible depending on the customer's request.

- SUS316 and titanium are available for the plate material.

Applications

| Food | Various seasonings, soup, animal-plant extracts, sugar liquids, high concentrate, amino acid, chlorella, juice, low salt soy sauce |

|---|---|

| Chemical | Latex, cosmetic ingredient, herbal medicine extract |

| Machinery and electric | Water soluble waste oil, plating wastewater, degreasing drainage, coolant wastewater |

- Global evaporator(GY : Coil rotation type)

- Suitable for the concentration of high viscosity liquid or solid content liquid

See more

- Global evaporator(GY : Coil rotation type)

- Suitable for the concentration of high viscosity liquid or solid content liquid

While holding the liquid in the separator, the heat transfer tube is rotated to concentrate. The quality is equal to or greater than the thin membrane centrifugal type, but it is also suitable for a small-volume production of a wide variety of products, and even high viscosity liquid or solid content liquid.

Features

- The concentration at low temperature is also good, obtaining high quality extract and a medicinal ingredient.

- Renewal of the heat transfer surface and the liquid boundary membrane avoids the deterioration of evaporation capacity due to scale stains and burnt.

- Suitable for the concentration of solid content liquid or high viscosity liquid (~10Pa・S).

- Cleaning and maintenance are easy due to the coil can be easily pulled out.