Retort Sterilizers

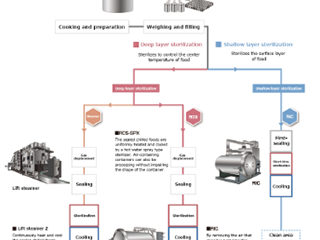

- High temperature, high pressure retort sterilizer

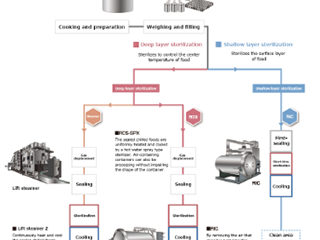

- There are three types of retort sterilizers that hot water spray type, hot water storage type and steam type.

We offer the best system for the customers depend on the product type and container shape, production volume and automation correspondence, etc.

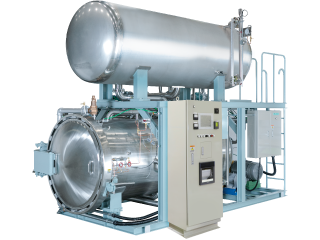

- Hot water spray type retort sterilizer(RCS)

- No variation in temperature, and possible to adapt for air-containing container.

See more

- Hot water spray type retort sterilizer(RCS)

- No variation in temperature, and possible to adapt for air-containing container.

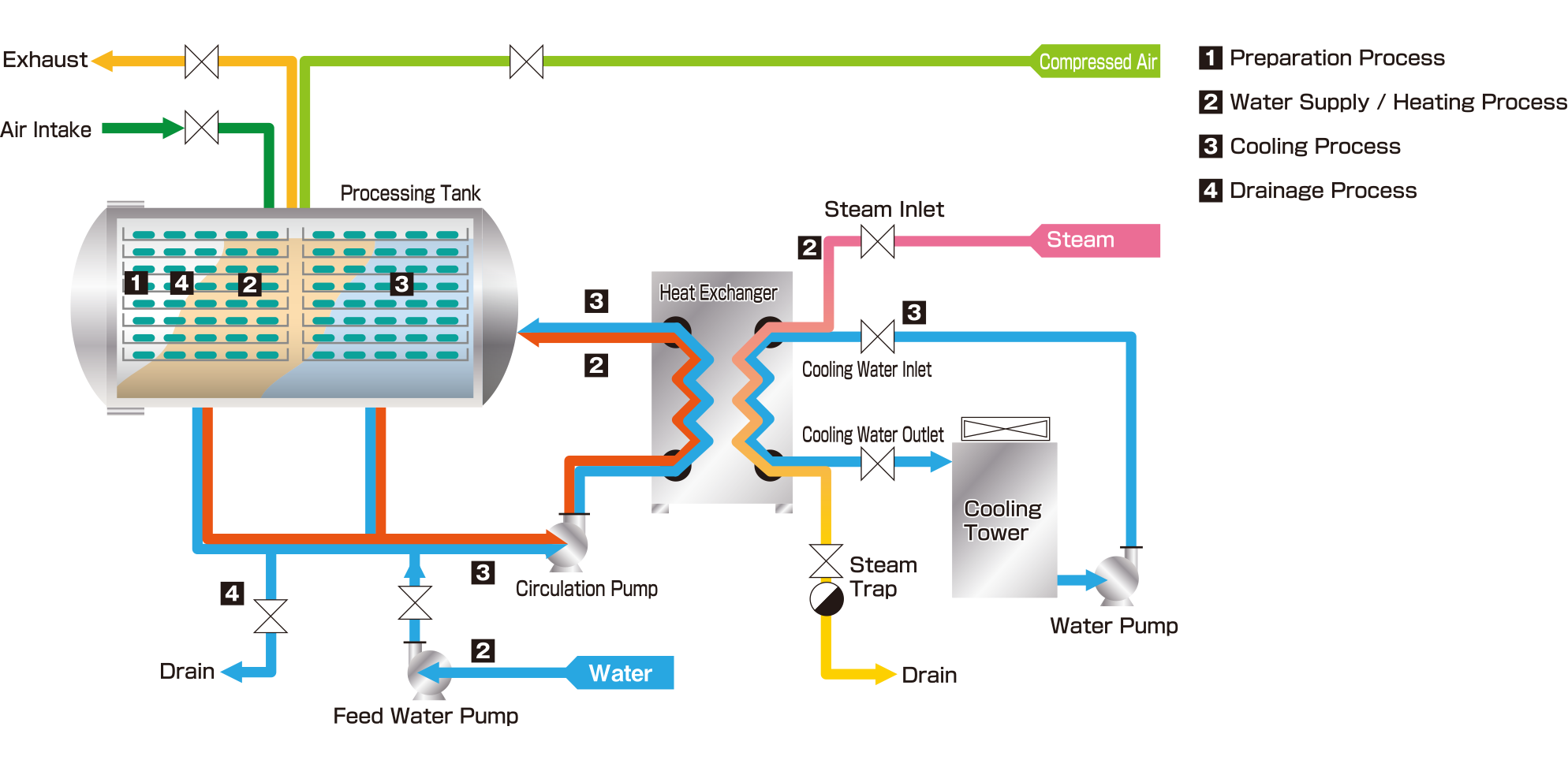

The sterilizer has very high temperature uniformity during the process of warming, heating and cooling, and no variation in temperature.

By performing indirect heating/cooling with a plate type heat exchanger, we prevent contamination from steam and cooling water and safely handle important products.

Features

-

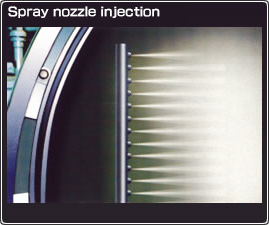

1. Heat sterilization by a four-way spray nozzle with uniform and high dispersion.

A four-way spray nozzle placed on each product tray enables heating and sterilization with the same quality at all up/down, right/left and back/forth tray positions.

The direction of the nozzle is clear, and uniform diffusion of hot water is achieved up to the center of each tray.Ideal system minimizes temperature variation inside the processing tank even in large size equipment

Capable of cooking, sterilizing of various product types

Capable of processing various product types by adding options.

-

2. Suitable for air-containing containers and glass bottles.

No influence of water pressure due to buoyancy or liquid depth, and even large size equipment can adapt for air-containing containers and glass bottles.

The retort foods in air-containing containers can be sterilized without deforming the container by the air-containing container processing system. -

3,1. Economical in energy saving and water saving type

The amount of holding water is 1/6 to 1/7 of hot water storage type, and the running cost is reduced by using the cooling tower which is standard in the plate heat exchanger.

The use of a hot water recovery system (optional) in large size equipment enables further energy saving and water saving. -

3,2. No secondary contamination

Since circulating water is sterilized with a plate heat exchanger, there is no secondary contamination in the cooling process and no pre-treatment of coolant is required by chlorine or the like. Also, there is no need to worry about contamination from heated steam.

-

4. Can be installed anywhere

No hot water tank is required, and because of its lightweight and compact design, it can be freely laid out such as installing on the second floor. It also improves the working environment by reducing noise levels which is difficult to achieve in direct heating.

Hot water spray type (Stationary type/Rolling type)

Standard functions

Uniform temperature distribution

Demonstration of uniform temperature distribution by FDA registration of Temperature Distribution Studies (Full-load of product).

As shown in the figure below, the sensors are placed on the center of the top, middle and bottom, also in two places of the each corner of the stacked trays, and the temperature is measured at a total of 24 locations in four columns.

Next-generation air-containing container processing system

Air-containing containers are processed with an advanced system.

- Patented next-generation air-containing container processing system (GGG).

A pioneer in the field of air-containing container processing system, Hisaka has been highly praised for a preparation and sterilization achievements of a wide variety of air-containing containers.

Adopting a thermal calculation theory formula based on actual data from further evolved processing systems, and by calculating the temperature of product in the air-containing container, we have been able to simulate subtle changes in the container air pressure, making possible accurate and highly repeatable pressure control.

Features

- Preparation and sterilization without deforming a variety of air-containing containers.

- Software application technology based on heat transfer cultivated from a lot of achievements and data.

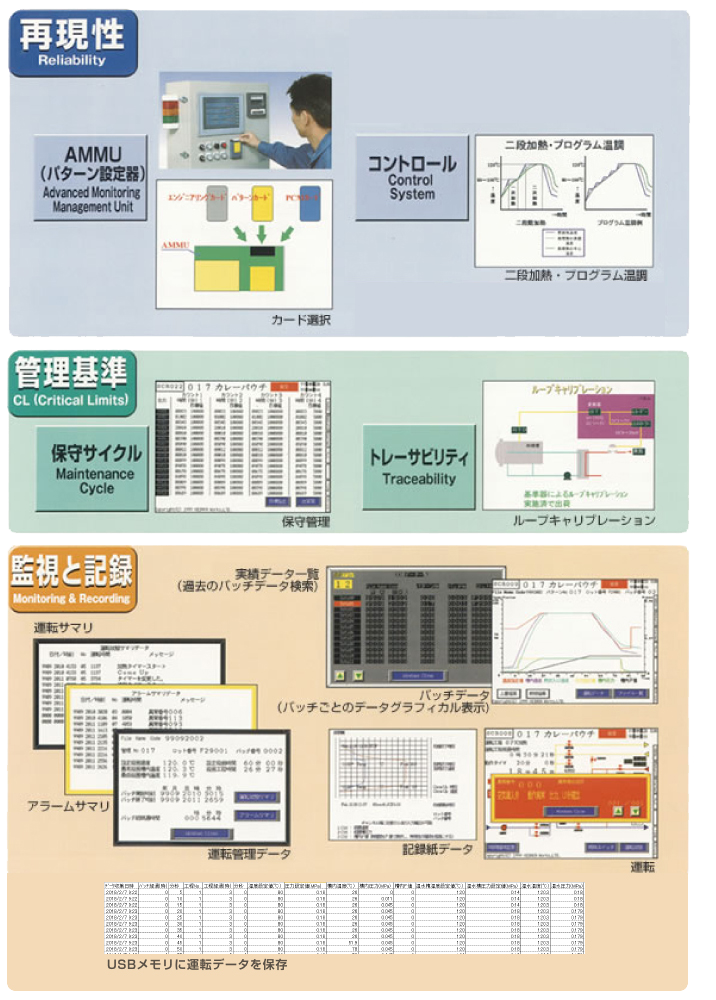

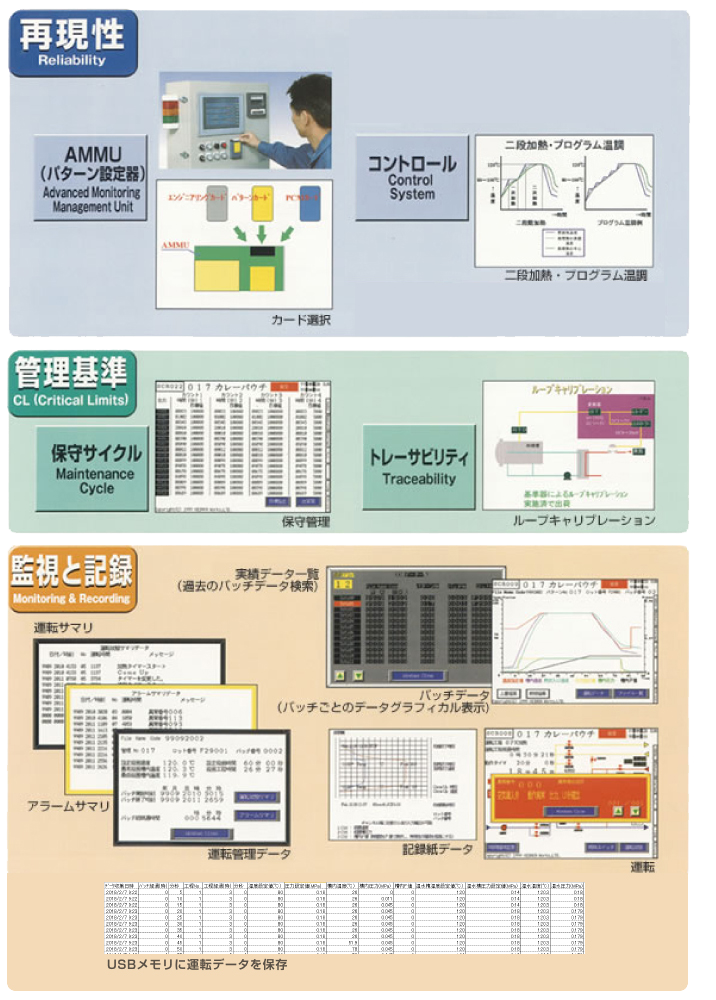

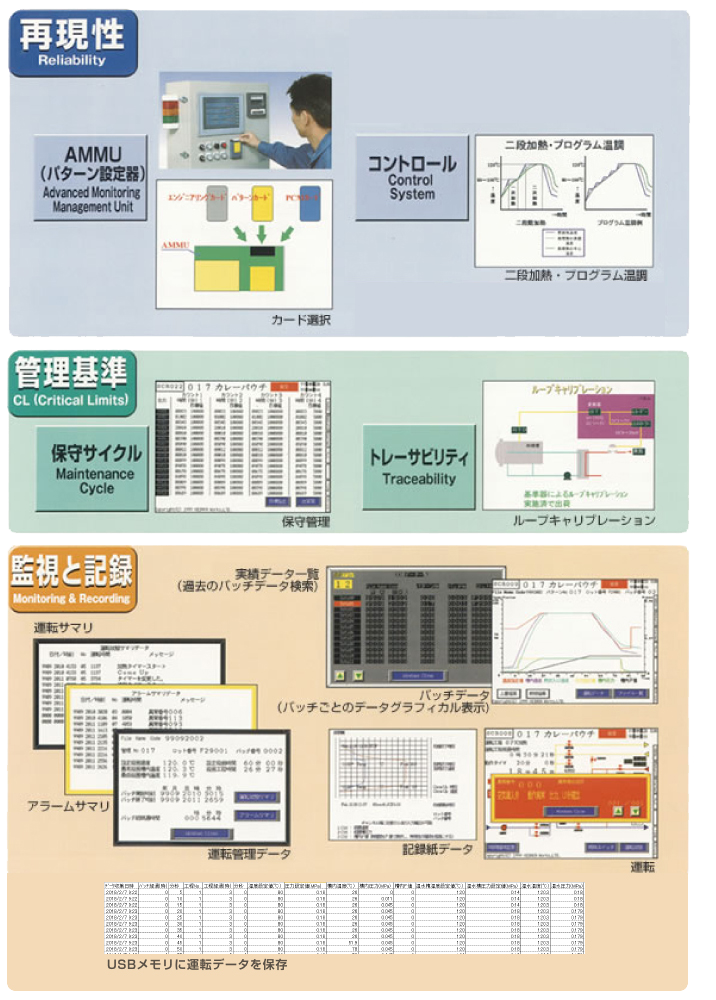

Correspond to HACCP

Employing optimal operations to ensure HACCP system is implemented in a rational and efficient way.

Features

- Hot water storage type retort sterilizer(RCS)

- Uniform sterilization is possible in a short time.

See more

- Hot water storage type retort sterilizer(RCS)

- Uniform sterilization is possible in a short time.

This is a highly versatile sterilizer that not only minimizes temperature variations by changing the direction of water flow, but also can select a rotating type (optional) that can be applied for large size cans and commercial pouches.

Features

-

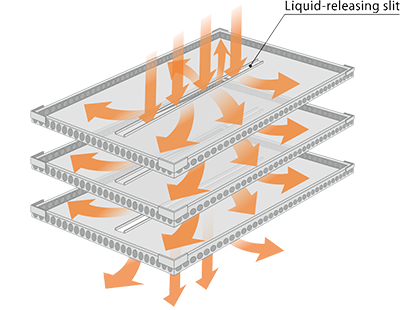

1. Dispersion of uniform water flow

By switching the water flow direction in the sterilization tank, uniform water flow to all directions is achieved.

The ideal system to disperse the water flow to the center of each product tray provides uniform sterilization.

Liquid-releasing tray

-

2. High temperature and rapid processing

By preparing hot water in advance and the heat sterilizing from the high temperature, enable high temperature sterilization in a short time.

-

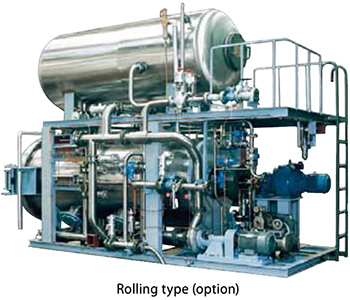

3. Support for the large size cans and commercial pouches by rotating type (optional)

In case of the stationary type, high viscosity foods using large size cans and commercial pouches are difficult to heat sterilize to the center in a short time. By stirring with rotational motion, high viscosity food can be uniformly heated to the center in a short time, and efficiently sterilized.

-

4. Compatible with air-containing containers

For the air-containing container, processing with optimal conditions including the preparation temperature of the hot water tank, processing temperature, temperature curve and pressure curve (air-containing container processing system).

-

5. Experienced control technology

Adopting AMMU (Pattern setting instrument) to set and register the planned sterilization conditions for food sterilization (HACCP-compatible). The ideal system to prevent the mistake of the setting operation by calling up the best sterilization condition by the pattern card by one touch, it is possible to correspond from one sterilizer unit to the unmanned operation in the factory (FA System).

Hot Water Storage Type (Stationary type/Rotating type)

Standard functions

Next-generation air-containing container processing system

Air-containing containers are processed with an advanced system.

- Patented next-generation air-containing container processing system (GGG).

A pioneer in the field of air-containing container processing system, Hisaka has been highly praised for a preparation and sterilization achievements of a wide variety of air-containing containers.

Adopting a thermal calculation theory formula based on actual data from further evolved processing systems, and by calculating the temperature of product in the air-containing container, we have been able to simulate subtle changes in the container air pressure, making possible accurate and highly repeatable pressure control.

Features

- Preparation and sterilization without deforming a variety of air-containing containers.

- Software application technology based on heat transfer cultivated from a lot of achievements and data.

Correspond to HACCP

Employing optimal operations to ensure HACCP system is implemented in a rational and efficient way.

Features

- Steam type retort sterilizer(RCS)

- Direct steam sterilization reduces running costs

See more

- Steam type retort sterilizer(RCS)

- Direct steam sterilization reduces running costs

The energy-saving equipment that is very high in temperature uniformity and can reduce running costs by sterilizing directly with steam. It has been adopted a lot in the processing of canned products, and can be applying to the air-containing pouch by installing the fan.

Standard functions

Correspond to HACCP

Employing optimal operations to ensure HACCP system is implemented in a rational and efficient way.

Features

- Options

- Wide range of options for better taste

See more

- Options

- Wide range of options for better taste

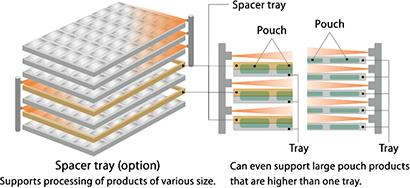

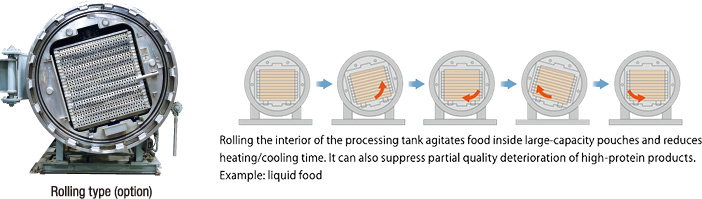

Rolling type*Support only with hot water spray retort sterilizer

Rolling allows the food in the pouch to be stirred and uniformly heated and cooled in a short time, greatly reducing the processing time and minimizing food quality degradation.

Features

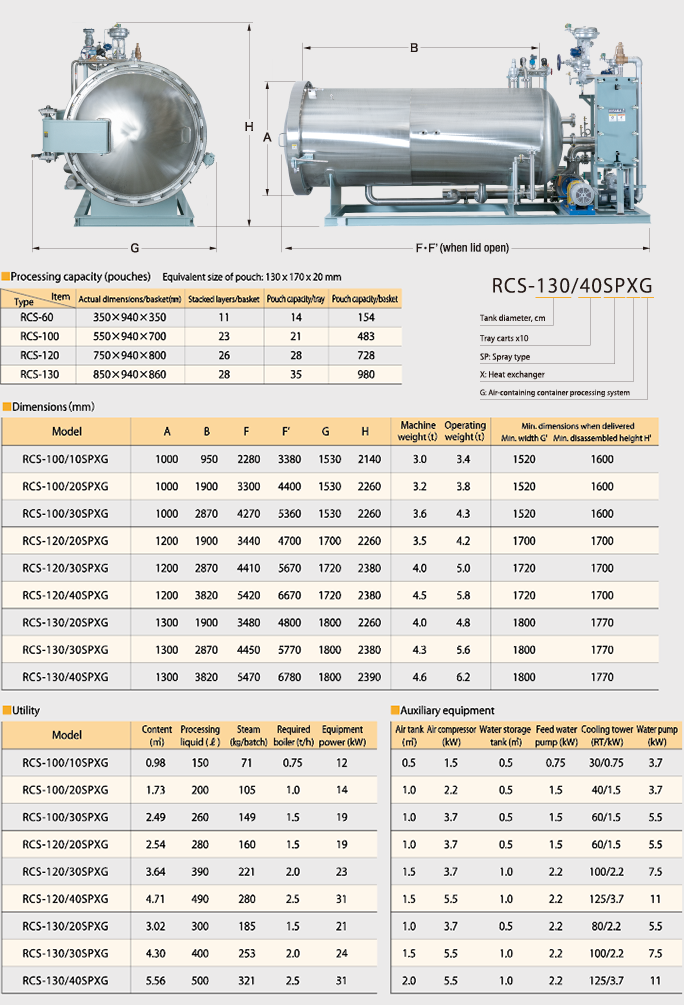

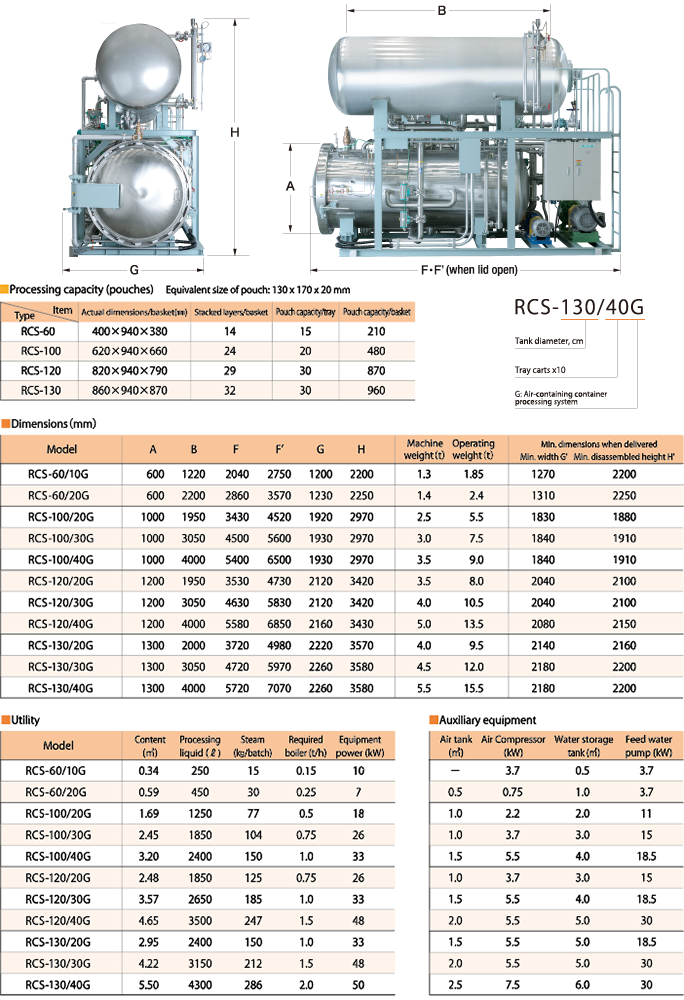

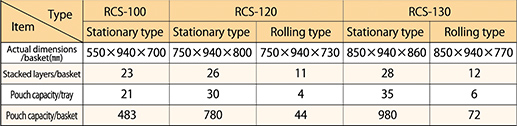

Processing volume (pouch)

Pouch conversion size

- Case of stationary type

130 x 170 x 20mm

- Case of rolling type

(3kg)

270 x 400 x 50mm

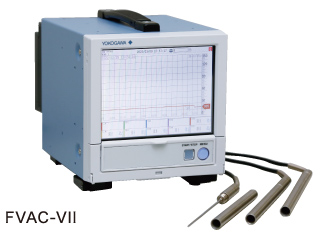

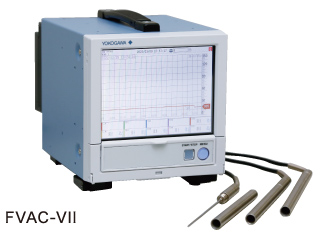

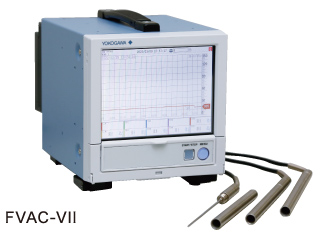

F-value computer

The best solution for the sterilizers.

This system collects and manages temperature and F value data by simultaneously measuring product temperature and calculating F value, which are important control items in the sterilizing process of food and pharmaceutical products, and is useful for confirming sterilization strength.

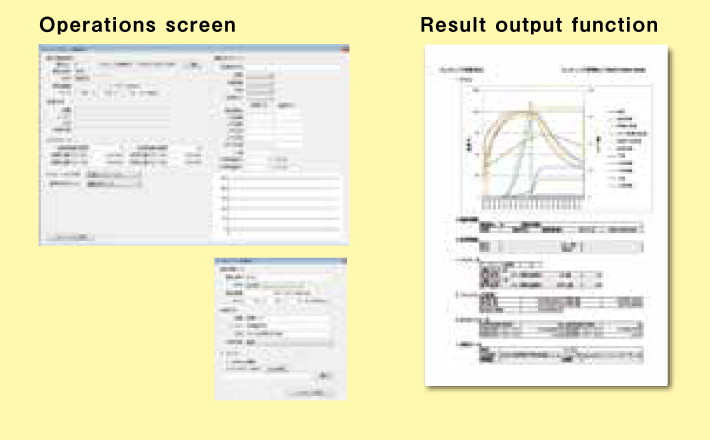

Standard functions

Achieve full sterilization management

- The dedicated application software, FVAC-VI enables centralized management of measurements, calculations, and various data.

- Temperature is measured with a thermistor sensor and F value is calculated. In addition, a calibration function in calibration, modification of F value calculation parameters, and analysis of collected data are available.

Support high-mix low-volume production

- Various setting information and measurement and calculation results can be saved on a memory card.

- Each setting such as F value parameters can be easily made for each lot and batch number.

Support HACCP certification work

- For production control and quality control, measurement data collected by FVAC-VI can be saved and analyzed on a PC.

Remote control is possible

- By connecting a remote contact signal for start/stop, the start/end of recording and F value calculation can be remotely controlled.

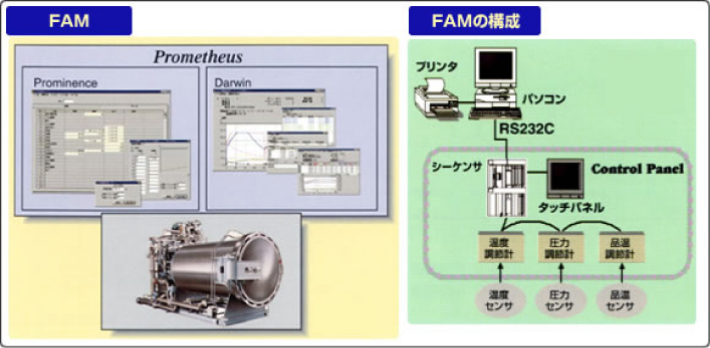

FAM (Flavor Ace Master)

Comprehensive system to improve productivity and creativity and create quality assurance

- It effectively supports production and quality control of food manufacturing processes, operational data management and documentation of sterilizer, and is effective for data analysis and management in the development and establishment of food and its processing methods and sterilization conditions.

- The system consists of a system that collects, monitors, and reports operational data, and a system that creates and manages resipes of operating and control conditions.

Simulation of product temperature

Parameter And Simulation System (PASS)

It collects and analyzes operation data of the sterilizer, and automatically creates and outputs daily reports of sterilizer operation to assist equipment management.

Support for test work and product development

Product analysis

- Analyze product temperature data

Simulating product temperature

- It predicts product temperature transition from a set ambient temperature based on product temperature data

Calculation of F- and C-values

- It predicts F-value (sterilization) and C-value (component attenuation value) based on product temperature prediction

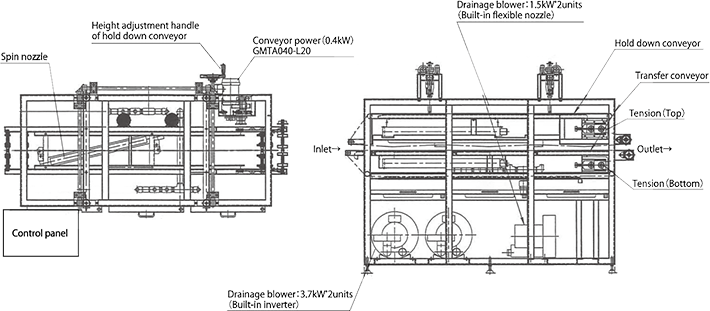

Air-blow type dehydrator

Air is used to remove moisture from the product after cooling.

Features

The spin nozzle dehydrates from the front and back surfaces in the first half of the process, and the flexible nozzle targets hard-to-remove areas in the second half to achieve a high dehydration rate.

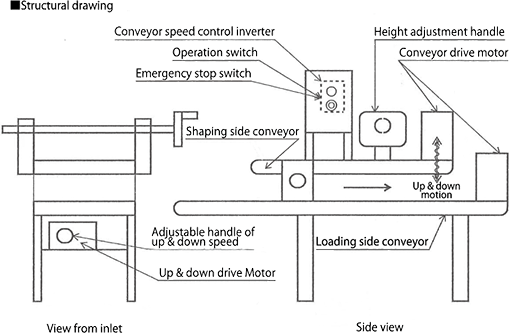

Shape arrangement conveyor

It intends to improve sterilization efficiency and increase the efficiency of box packing operations by ensuring uniform thickness of the product.

Features

The conveyor on the side to be shaped is moved up and down to beat and stretch the product to handle products with high solid content.

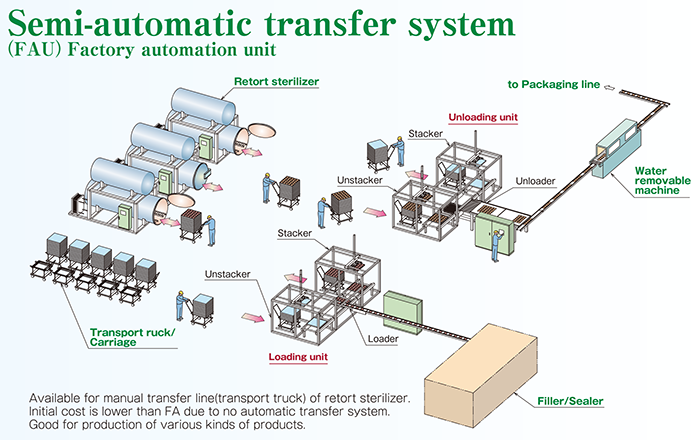

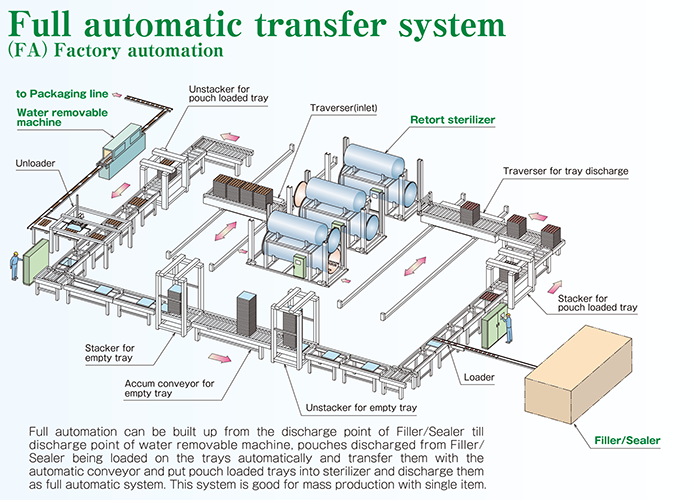

- Factory Automation System

- Total automation system achieving energy saving and efficient production line

See more

- Factory Automation System

- Total automation system achieving energy saving and efficient production line

Factory Automation System

Reducing labor costs

By letting FA takes over the work done by labors, it is possible to drastically reduce labor costs

Labor-saving

Releasing the operators from hard work, such as lifting heavy trays

Custom-made design

Proposing the optimal design for the customer's facility environment

Reliability and extensive experience

Receiving a high reputation of our extensive experiences at the pharmaceutical industry which requires sophisticated technology and reliability

FA system CASE STUDY

- Retort sterilizer tester

- Testing machine producing tomorrow's foods.

See more

- Retort sterilizer tester

- Testing machine producing tomorrow's foods.

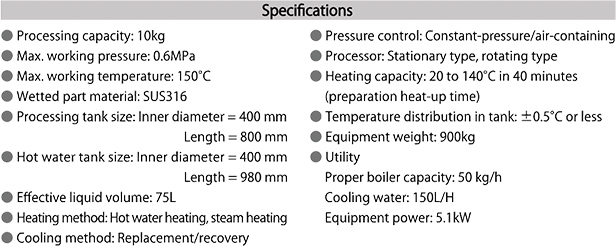

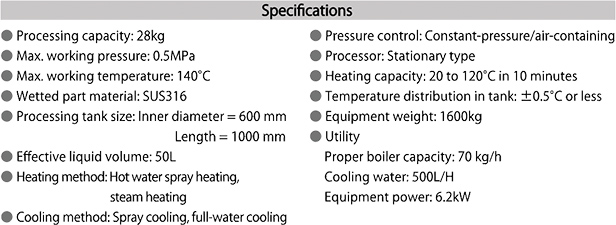

Hot water storage type retort sterilization tester

(RCS-40/RTGN)

Hot water spray type retort sterilization tester

(RCS-60/10SPXTGS)

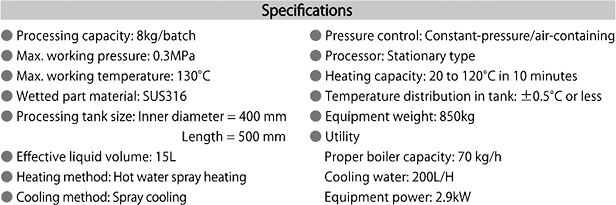

Compact hot water spray type retort sterilization tester

(RCS-40SPXTG)

*Applicable to small-sized pressure vessels

- Related facilities

See more

- Related facilities

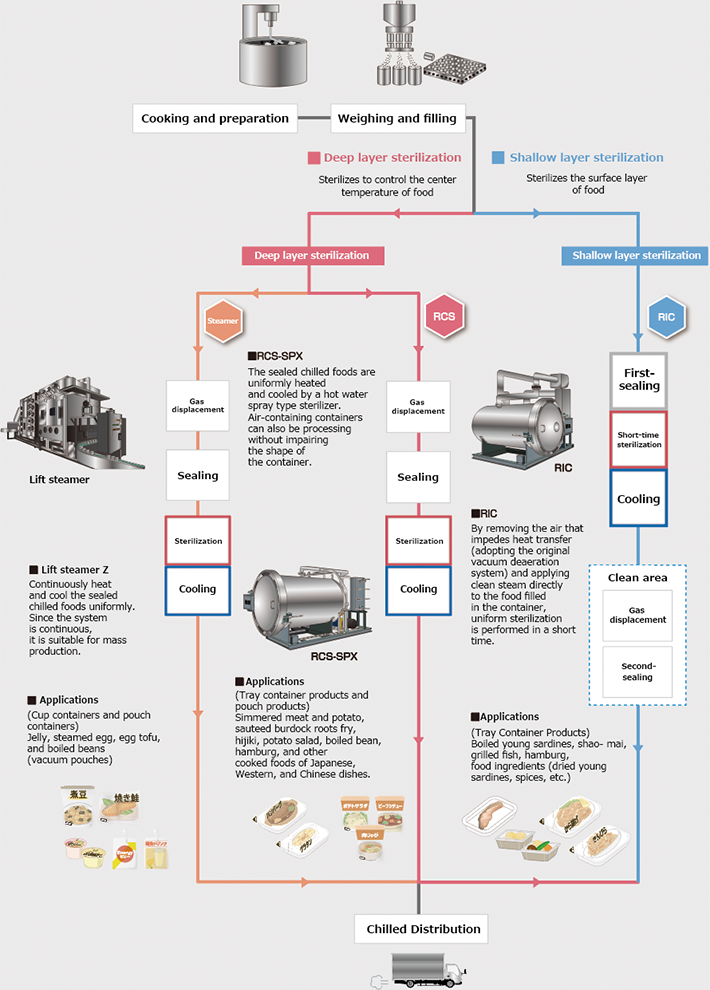

Production line for long life chilled foods