Supercritical fluid processing machine

By using supercritical (subcritical) fluid of CO2, water and alcohol as a dyeing technology for the near future, we have manufactured the world's largest dyeing machine while assuming practical production that conduct dyeing, reacting, extracting, separating, washing, dissolving and oxidizing.

The CO2 supercritical technology, which is environmentally friendly because drainage is not discharged, is expected to be applied not only for dyeing but also for special processing such as washing and functionalization.

- Supercritical fluid processing machine

- Reaching the dreams of dyeing technology that

uses no water at all.

See more

- Supercritical fluid processing machine

- Reaching the dreams of dyeing technology that

uses no water at all.

This is a revolutionary dyeing machine that reuses CO2 from liquid to supercritical to gas to liquid

in a closed system, and is effective in reducing environmental impact and is not affected by

water resources.

the supercritical fluid in the tank.

the next process, and is recovered and stored as liquid CO2.

Features

- Reducing the energy by 43%.

- No water and chemicals (dispersant, leveling and RC agents) is required.

- No drainage treatment and dryer is required.

- Carbon dioxide is available for recovery (Recovery rate : 96%).

- Safe design of 30MPa withstand pressure.

- Supercritical fluid processing machine

(HVI-SC)

- Realizing the functional processing, reforming,

extraction, and precision washing without

using water

See more

- Supercritical fluid processing machine

(HVI-SC) - Realizing the functional processing, reforming,

extraction, and precision washing without

using water

This machine supports various types of processing under supercritical (subcritical) conditions of

high temperature and high pressure (300℃ and 30 MPa).

High quality

- Without using water, functional processing, reforming, extraction of high-grade components, and precise cleaning are possible.

- The high diffusivity reaction and synthesis are easily controlled, and the recovery rate of the target substance is improved.

- Also be applied to co-solvents and surfactants.

- Extracts and products can be separated and precipitated in dry condition by pressure drop or vaporization.

- Diffusing into the amorphous parts inside the polymer, and the processing and washing of microscopic pores are possible.

Wet heat and supercritical (subcritical) processing of water system

Hydrothermal reaction can perform an etching cutting and decomposition of high polymer area that do not require chemicals.

Applications

- Recycling applications, including chemical products.

- Reforming and decomposition of amorphous parts in the wet heat zone (ex : Monosaccharification and shape stabilizing processing of cellulose).

- Chemical recycling through pyrolysis, oxidative decomposition, and hydrolysis.

- Hydrolysis of water similar to acid or alkali treatment through hydrothermal reaction or increase in ionic volume.

- Improving the availability of biomass.

- Reforming, decomposition, and degradation product.

- Decomposition and oxidative decomposition by thermal reaction using high heat.

High temperature/high pressure/vacuum processing equipment

Performing various processes under high temperature, high pressure, and vacuum conditions

- Degreasing and washing

treatment equipment (LLG)

See more

- Degreasing and washing

treatment equipment (LLG)

By uniformly circulating liquid under high temperature and pressure, this is a labor saving and unmanned system capable of not only degreasing and washing of filters and hollow fibers but also coloring and plating of nonwoven fabrics.

- High temperature/high

pressure wood bleaching and

dyeing equipment (LLG)

See more

- High temperature/high

pressure wood bleaching and

dyeing equipment (LLG)

This is a labor saving and unmanned system capable of bleaching and dyeing the wood (veneers) by uniformly circulating the liquid under high temperature and pressure.

- Vacuum pressure impregnator

(HVI : vertical type)

See more

- Vacuum pressure impregnator

(HVI : vertical type)

The impregnation process of wood, composite material, and high-density materials is possible.

We also provide the most suitable testing machines for new product development.

The use of sanitary piping and the use of a circulating pump to clean the inside of the tank make maintenance and inspection easier.

Features

- Stable supply of high-quality products by accurately controlling temperature, pressure, and vacuum conditions.

- By circulating the processing fluids, the contact between the workpiece and processing fluids becomes uniform, and uniform processing is possible.

- Installation of various safety devices and warning devices to ensure safe operation.

- Use of organic chemicals is also possible due to explosion-proof specifications.

Applications

- Steaming process

- Vacuum and pressure impregnation of composite materials

- Liquid circulation treatment (bleaching and dyeing)

- Gas processing

- Wood processing (pretreatment, bleaching, dyeing)

- Resin impregnation of high-density, porous materials

- Various chemical and gas treatment

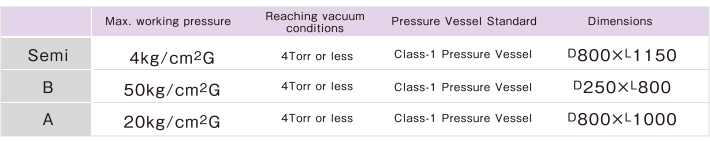

Specification

* Contact us if other conditions are required, such as temperature, pressure, and vacuum conditions.

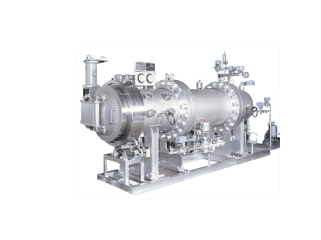

- Vacuum pressure impregnator

(HVI : horizontal type)

See more

- Vacuum pressure impregnator

(HVI : horizontal type)

Various types of processing suitable for wood, composite materials, high-density materials, etc.

are possible.

It also supports the new utilization technology of wood (high-temperature/high-pressure press molding, liquefaction, thermal plasticizing, vacuum pressure impregnation).

- High-temperature and

high-pressure press molder

(HTP)

See more

- High-temperature and

high-pressure press molder

(HTP)

It is possible to carry out a wide variety of processes (steaming, press forming, etc.) under

high temperature and high pressure conditions, such as composite molding, wood molding,

and laminated single plate processing.

- High-temperature and

high-pressure wet heat

treatment equipment

See more

- High-temperature and

high-pressure wet heat

treatment equipment

Hydrothermal reactions of high-temperature hot water and steam can be used to hydrolyze, reforming, react, and decompose a high molecular compound (proteins, cellulose, etc.).