In order to help customers establish optimal systems, various testing machines are permanently installed and tested on a daily basis.

The bring-in test is also available to check the quality of processed products before installed our actual machines.

Bring-in test

-

- Available models in

bring-in test - CUT-ZR / CUT-MR / CUT-AR / LLC

- Available models in

Dyeing

-

- Industrial materials

(car seats) - Industrial materials, including car seats, require high quality and high productivity.

CUT-AR has a productivity of more than 1.5 times

that of conventional products, high quality,

and high reproducibility.

- Industrial materials

-

- Industrial materials

(medical materials) - Not only high productivity, but also elasticity, strength, and lightfastness are required of the base fabric used in poultice and plaster.

Hygiene considerations are also necessary.

- Industrial materials

-

- Clothing

(sports, outdoors, and innerwear) - In the clothing field (sports, outdoors, and inner),

it tends to use a fine denier yarn for improving

the texture and functionality of the fabric, making

dyeing difficult.

Prevention of dyeing problems and defects is essential.

- Clothing

-

- Functional fibers

(micro and nanofibers) - Compared to conventional fibers, it has a very

large fiber surface area and is expected to use in

various fields.

Integrated processing from fiber division process to dyeing of sea-island structure is possible.

- Functional fibers

-

- Lining

- In the field of lining, which has become a standard, strict cost reductions and high productivity are required.

Reducing the accident rate through various systems contributes to cost reduction

-

- Interlining

- It is possible to process extremely lightweight materials (about 20 g/m2).

By suppressing twisting during machining, it is possible to have two or four passing, which leads to an improvement in productivity.

-

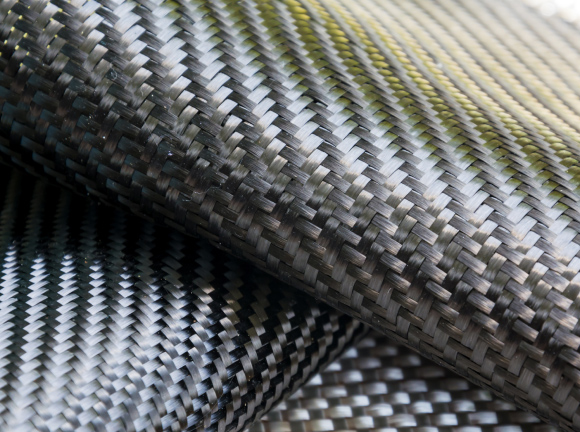

- Natural/Composite Fibers

- It is possible to run at a low nozzle pressure, which is unprecedented, and solves the problems of fluffing, felting, rubbing and wrinkling.

Stable low-tension operation enables machining without tacking, such as bare sheeting.

High temperature wet heat

-

- High temperature wet heat treatment equipment

- High-temperature, high-pressure steaming is possible using saturated steam of a high-pressure boiler

(2.94 MPa).

It is effective in decomposing and modifying organic matter, and is used for roasting, vulcanization, morphology stabilization, and waste treatment.

-

- Wood press molder

- Under a saturated steam atmosphere with high temperature and pressure, wood can be softened, molded, and fixed.

This enables the specific gravity of the wood to be increased to 1 or more, and the strength as much as the ebony can be obtained.

-

- Blasting treatment equipment

- After high-temperature, high-pressure steaming using saturated steam from a high-pressure boiler

(2.94 MPa), the pressure is released instantaneously to crush the product.

It is effective for decomposition and reforming because it is subjected to high-temperature wet heat treatment.

-

- Vacuum pressure impregnator

- Vacuum impregnation (water-sealed vacuum pump) and pressure impregnation (air, nitrogen) can be performed.

This product can be used for impregnation of wood, fiber, metal, etc.

Supercritical

-

- Polyester dyeing

- It is possible to dye polyester fibers by taking advantage of the properties of supercritical fluids.

Since no water is used, drying is unnecessary,

drainage is not discharged, and it is attracting attention as an environmentally friendly dyeing formulation.

-

- Dyeing of PP (polypropylene) dye-resistant fibers

- PP dyeing, which was not possible with conventional water-based dyeing, is possible.

Currently, it has not yet been industrialized, but it

has been demonstrated at the test level.

-

- Injection of metal complexes into fibers

- Formulations for injecting metal complexes into fibers in supercritical fluids for use in conductive and magnetic plating have been investigated.

This is expected because it offers significant advantages compared with conventional plating formulations.