Periodic inspection

Only taking the annual inspection with class-1 high-pressure vessels is not enough for maintaining the performance of sterilizers.

Daily inspections and periodic inspections must be carried out and maintenance needs to be carried out according to the conditions.

We recommend a "periodic inspection" in which a specialized service staff checks and adjusts important points and diagnoses equipment malfunctions.

Inspection details unique to equipment manufacturers

- Conduct a trial run of the equipment after a periodic inspection.

- Staffs who understand the operation of the various valves and the operation of each process are dispatched.

- Advice on maintenance

- Propose systematic maintenance while prioritizing

- Measure the temperature in the tank with data trace (compact data logger).

- Check that the sensor is not shifted (simple calibration).

* If the deviation is large, suggest calibration.

Content of inspection

In the case of hot water storage type sterilizer

- Inspection item

-

- 1Checking the automatic operation

- 2Checking the operation of the automatic valve

- 3Checking the operation of the pump

- 4Checking for leaks of the cylinder valve seat

- 5Checking for leaks of the check valve of the ejector air inlet

- 6Checking for leaks of the feed water check valve

- 7Checking for clogging of the air vent silencer

- 8Checking for leaks of the automatic valve seat

- 9Checking the pressure reducing valve with filter

- 10Checking the operation of the air compressor

- 11Checking the liquid level gauge

- 12Checking the electrode and holder

- 13Checking the operation of the sensor

- 14Checking the operation of the indicator adjustment of the temperature indicator controller

- 15Checking the operation of the indicator adjustment of the pressure indicator controller

- 16Checking the operation of the temperature and pressure recording indicator

- 17Checking the loading and unloading of the holding vehicle

- 18Checking the lid opening/closing operation

- 19Checking the opening degree of the manual valve

- 20Checking the state of consumption of sacrificial materials for hot water tanks and aluminum comb plate.

- 21Checking the operation of the rotating body (rotating type only)

- 22Checking the operation of the holding unit (rotating type only)

- 23Checking for leaks of liquid and air from each part

- 24Checking that the operation method is correct

- 25Checking the status of spare parts stock

- 26Checking the battery replacement status of the sequencer

- 27Checking the surrounding environment

- 28Checking the pointing accuracy of the temperature pointing controller.

- 29Checking for temperature deviation of the temperature in the tank by data trace

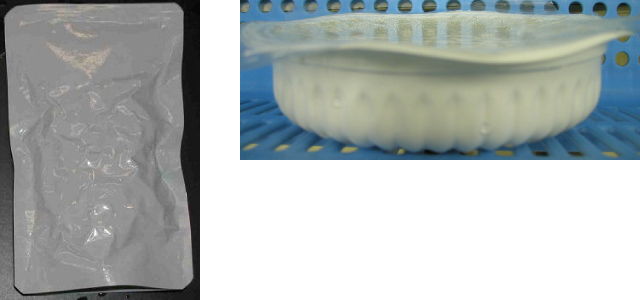

Risk of inspection and maintenance failure (in the case of retort sterilizer)

- Unusual pressure

- The product may be deformed or damaged.

- Temperature error

- If the temperature is low, the product may not be sterilized enough.

If the temperature is high, over-sterilization will occur. - Others

- If an operation error occurs, the process stops halfway and production stops.

Hot water or steam above 100℃ may be emitted dangerously.

The risk of product disposal due to trouble increases.

Preventing troubles with preventive maintenance with periodic inspections eliminates sudden expenditures and consequently saves maintenance and management costs in total.