Pharmaceutical purposes sterilizers

This is a pharmaceutical sterilizer that can respond to cGMP (Good Manufacturing Practice) by strictly controlling temperatures and pressures,

such as infusions for pharmaceutical purposes, injections, and medical devices.

Hot water spray, hot water storage, steam, and ventilation types are available.

- Hot water spray type sterilizer

- With strict temperature and pressure control, cGMP (the current Good Manufacturing Practice) can be applied.

See more

- Hot water spray type sterilizer

- With strict temperature and pressure control, cGMP (the current Good Manufacturing Practice) can be applied.

The hot water spray type, which focuses on the uniform dispersion of heating/cooling water, minimizes variations of the F0 value and eliminates steam contamination in the sterilization tank

for indirect heating/cooling.

We provide validation that complies with the latest cGMP (the current Good Manufacturing Practice) by strictly controlling temperatures and pressures, from small size equipment to large size equipment exceeding 50 m².

Rather than a single sterilization unit, we propose a sterile tray for product alignment, as well as

a loading/unloading device, also a highly reliable fully automated and labor saving system.

Features

- Four-way spray nozzle on all-stage of trays achieves extremely uniform temperature distribution.

- No influence of water pressure due to buoyancy or liquid depth, and even large size equipment

can adapt for air-containing containers and glass bottles. - Flexible packaging materials, such as soft bags, do not deform product containers due to

the air-containing container processing system.

- The small amount of water in the sterilization tank reduces running costs and also achieves energy and water conservation through the hot water recovery system.

Applications

Infusion bag/bottle, prefilled syringe, ampule/vial, hygienic cotton, catheter, oral/enteral preparation, etc.

- Hot water storage type sterilizer

- Uniform water flow is realized at all positions allowing uniform and efficient sterilization to

the center.

See more

- Hot water storage type sterilizer

- Uniform water flow is realized at all positions allowing uniform and efficient sterilization to

the center.

By switching the water flow direction in the sterilization tank, uniform water flow to all directions

is achieved.

It can be uniformly heated to the center in a short time even in the product of large volumes and

high viscosity by stirring with a rotating operation, and the sterilization treatment with less product deterioration is possible.

Strict temperature and pressure control provides a reliable system.

Features

- The liquid flow switching system minimizes temperature variation and achieves uniform sterilization for all products in the tank.

- By preparing hot water in advance, unnecessary time is thoroughly cut, and high temperature and short-time sterilization is realized.

- Rotating the sterilization tank enables precision and short-time sterilization for high viscosity liquid and jelly liquid preparations.

- Temperature and pressure are controlled according to the characteristics of each product using

the air-containing container processing system to prevent container deformation.

Applications

Oral liquid diet and enteral nutritional supplement

- Steam type sterilizer

- Applicable and significantly increase sterilization effects.

See more

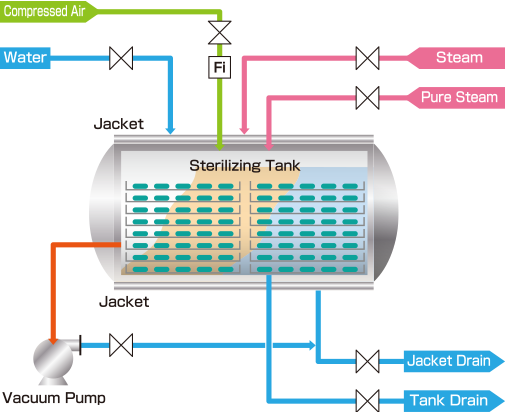

- Steam type sterilizer

- Applicable and significantly increase sterilization effects.

The sterilization effect is greatly improved in the method which reduces running cost by sterilizing

directly with steam, and combines degassing and recovery pressure.

We use pure steam for sterile formulation lines and sterile assembly processes, and guarantee

the sterilization of sterile devices with a highly sanitary structure.

We provide validation support conforms to the latest cGMP (Pharmaceutical manufacturing standards),

and offer the optimal equipment suitable for your requirements by design that matches the building,

production facilities and line layout.

Features

- It can be designed to suit the customer’s needs, such as the size of the unit, automation of

door opening, installation location and finishing method.

- The pure steam generator necessary for the heat source of the sterilizer also calculates the steam usage fee and can be selected by the optimum design.

- The chamber can be selected cylindrical cylinder type and square type, and jacket structure can be adopted for heating and cooling.

Applications

Sterilization and drying of medical appliance, medical equipment, dust-free clothes, ampoules, vials, etc.