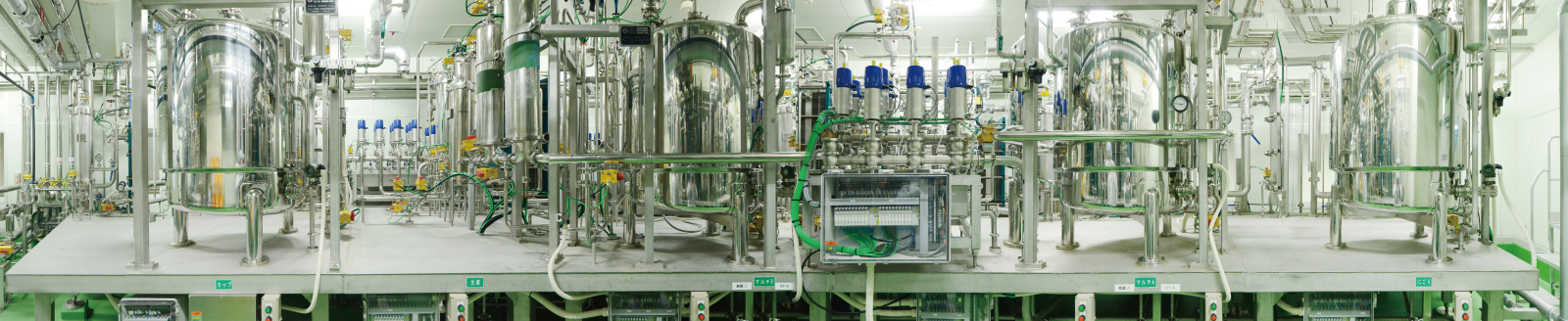

By combining tanks, piping, pumps, etc., as well as equipment alone, experienced designers propose optimal plant equipment for their customers.

We have a large number of experiences in a wide range of fields, such as liquid preparation plant and crude drug concentration plant.

Please feel free to contact us and we are looking forward to supporting you.

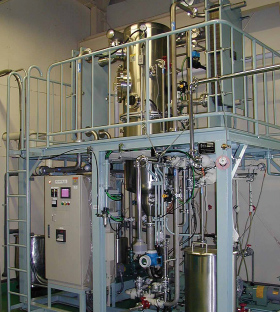

Example of pharmaceutical plant construction

01Extract extraction and concentration plant

We will consistently design and construct extraction, concentration, preparation, sterilization, and drying processes for extract manufacturing plants for herbal medicines, crude drugs, and functional food raw materials.

Based on our large number of experiences as a manufacturer of the equipment used in each process, we propose an optimal plant system that meets the needs and applications of our customers.

02Automatic transfer plant for infusion product sterilization

It is applicable to a variety of packaging materials, including soft bags and plastic bottles for infusion.

HISAKA, who boasts the top share in the infusion sterilization field in Japan, offers a safe and secure automation system, so please feel free to consult us.

03Preparation plant

- Tank manufacture

- Designing and manufacturing of tanks suited to applications such as agitation, melting, storage, and heating and cooling.

First-class and second-class pressure vessels and explosion-proof devices are also possible. - Sanitary piping and construction

- Consult us for the special piping such as construction in a clean room and explosion-proof facility.

- Plant engineering

- Consistently respond the works including the construction of tanks and piping, design and construction of electrical control, and maintenance.

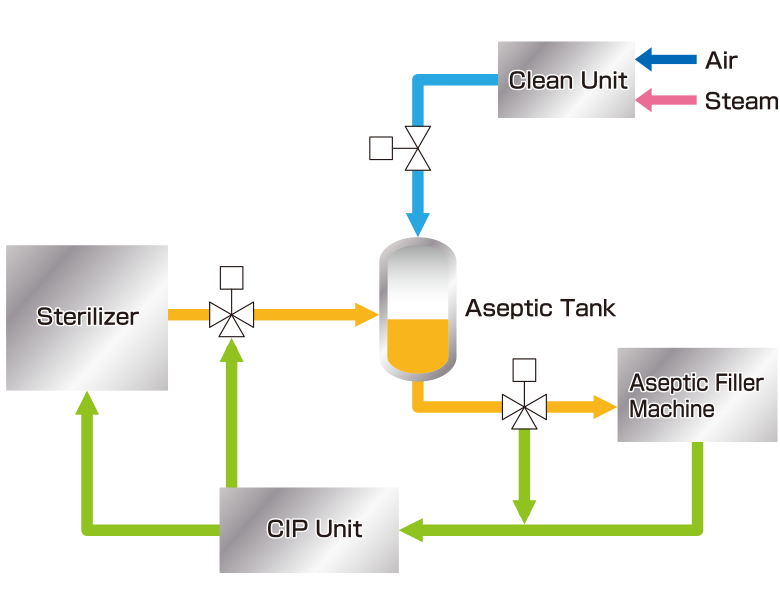

- Aseptic system

- The sterilization and cleaning systems are managed automatically in the continuous system from the sterilizer to the aseptic filler.

Example of food plant construction

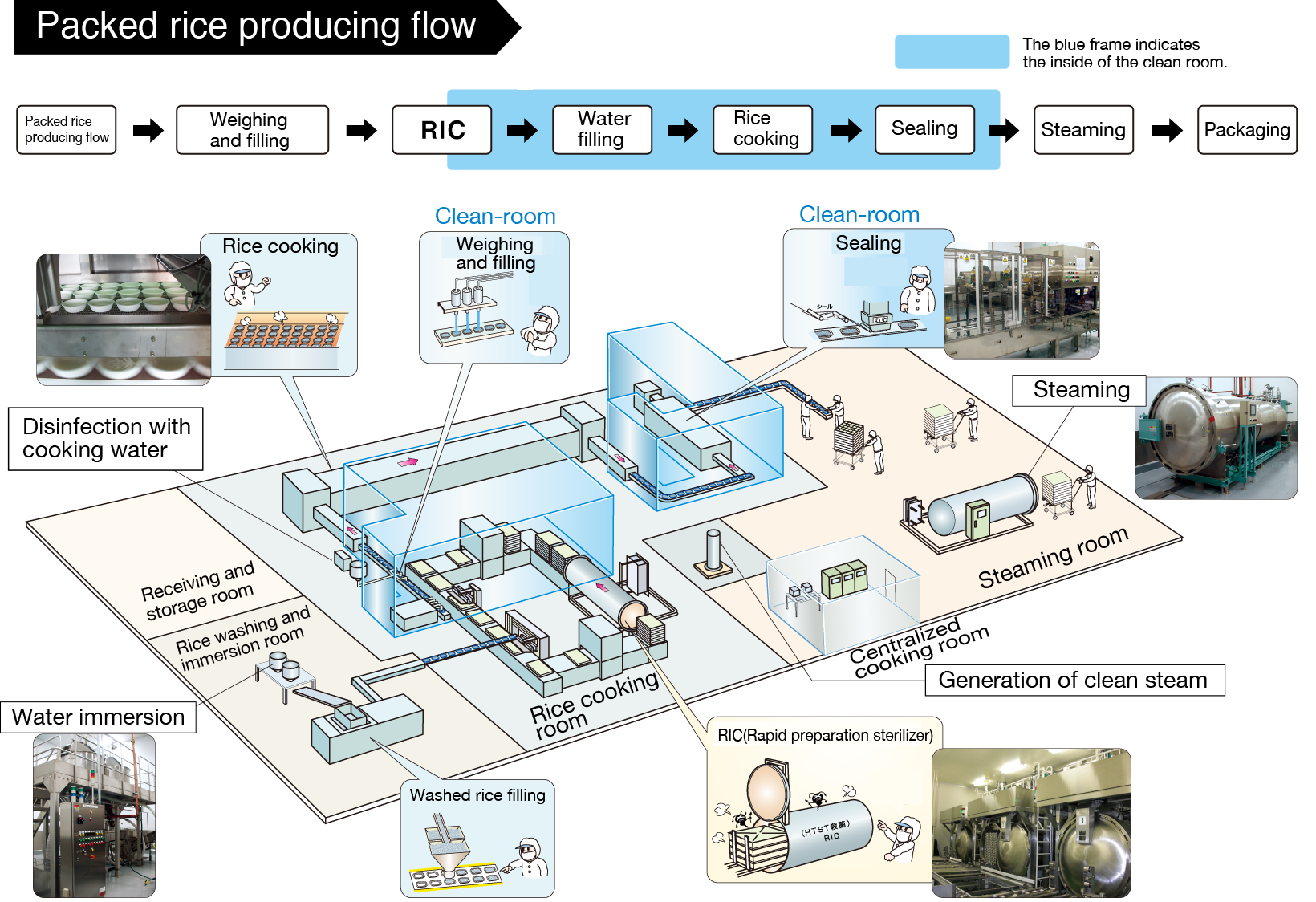

01Sterilized packed rice cooking plant

This is a compilation system of HISAKA's technologies.

02Sake filling plant

- Outside sake storage receiving facility

- Sterilization

- CIP device

- Centralized control room

- Improved yield through sake recovery system

- Achieved labor saving by automatic control system

- Space saving and automation of liquid type switching equipment

03Extract producing plant

Plant engineering, which can only be done by manufacturers who know the individual equipment, offers the most appropriate plant for the purpose and application of the customer.

HISAKA products are used in the extraction, concentration, sterilization, and drying process, which is the main process of extract producing plants for meat, fish, seaweed, and other products.

- Extractor

We propose an optimal extraction system (normal pressure, high pressure, alcohol, etc.) according to the application.

We propose an optimal extraction system (normal pressure, high pressure, alcohol, etc.) according to the application. - Concentrator

We propose an optimal concentrator (from one-pass type, flash type, and global type) for each application.

We propose an optimal concentrator (from one-pass type, flash type, and global type) for each application. - Retort sterilizer

Our industry-leading technologies can be used to create safe, secure, and stable products.

Our industry-leading technologies can be used to create safe, secure, and stable products.

- Liquid continuous sterilizer

We propose an optimal sterilizer (from plate type, tube type, injection type, and joule type) for each application.

We propose an optimal sterilizer (from plate type, tube type, injection type, and joule type) for each application. - Vacuum belt dryer

Vacuum low temperature drying can be used to produce extract powders with high quality and excellent solubility.

Vacuum low temperature drying can be used to produce extract powders with high quality and excellent solubility.